Ralph and I work together on the allotment. Really, it’s my area but he’s very good with words so he’s done most of the writing. His words are in italics.

Just for the record, in my 40s, I spent 5 years studying horticulture and landscape design, acquiring the RHS Diploma in Horticulture and a bronze medal at RHS Hampton Court Flower Show back in 2007. I studied long and hard and enjoyed every minute of it, making some of the best friends ever through the trials and tribulations of studying and then producing a garden for an RHS show. For over 20 years, I’ve followed permaculture methodology and tried to incorporate this in my designs and when working in the garden, down amongst the dirt. While on this journey, I plan to finally start, and hopefully finish, the online design course I signed up to a couple of years ago to gain a recognised qualification in Permaculture Design. I say all this because it was ironic that I then just scrawled a design for Joanna’s garden on a scrap of paper. I did ‘walk the land’ first though, if that’s any consolation…

Ralph gives the background: “The garden is about 100 metres below the top of a south facing hillside. The hill is at times very steep (over 45 degrees) interspersed with shallower sloping ‘pockets’ that hold a good depth of top soil. The whole slope probably runs for 500 metres or more down into the Ea river valley which enters the sea a short walk away.

The aspect of the site is good for a vegetable garden. It gets maximum sunlight and has a good airflow from the south east through the valley to reduce likelihood of fungal diseases. The site is also unlikely to suffer frost since warm air will rise up the valley from the sea below keeping it from freezing.

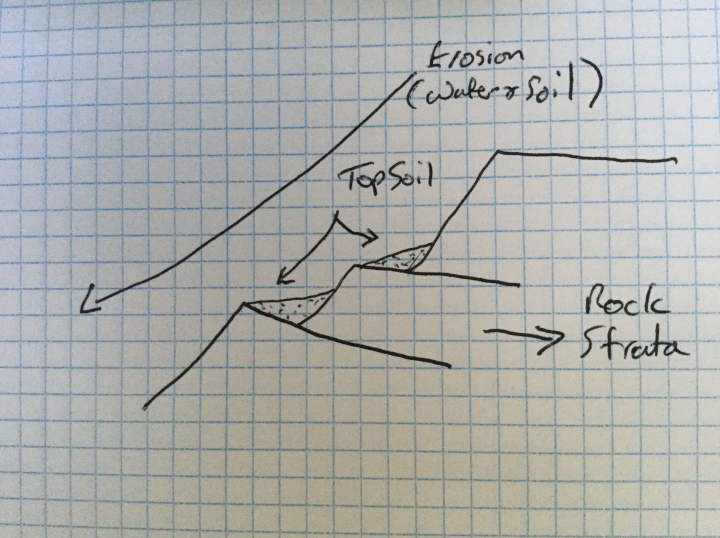

The geology of the site is also favourable (see sketch). The underlying rock appears to be a soft sedimentary mudstone that is strongly stratified and easily weathered. The hill above the garden is grazing land and has been for many centuries. The products of erosion has combined with humus from the land above and collected in the pockets created by the underlying bed rock. These pockets now contain a depth of top soil that is far deeper than may have been possible had the site been more level. Water will also flow down the hill and be held up in the pocket reducing the need for watering during dry spells.

When working with nature in permaculture an understanding of the land is essential. Our ideal is to work directly with the natural processes; an approach likely to give the most favourable balance between input (work) and output (production) in this case food. Sometimes however, we need to adjust things a little to suit our needs. This should be done thoughtfully so that the flow is still with nature. The bigger the diversion, the larger the cost of construction and maintenance as nature seeks to restore itself.”

As for me, I was immediately taken by the allotment. It was quite overgrown except for a square at the bottom of a serious slope, which Joanna had cleared and from which she had already successfully cropped a variety of vegetables. Onions and potatoes had been lifted and stored as had many courgettes and the subsequent marrows which appear when your back is turned. The courgette plants had somewhat taken over and many appeared to be some kind of gourd. There was also a swathe of marigolds slicing through the green with their orange and red petals, all sparkling and what not.

The area had be grazed by livestock in the past and, although eventually became totally overgrown with brambles, the soil is the best I’ve ever had to work with. Thankfully, the brambles had all be cleared away and all I had to do, initially, was some serious weeding!

Whilst Ralph was busy elsewhere, I started by clearing the top nearest the house (and compost bin) and soon noticed how very steep it was and how uncomfortable that made it for working – and walking! The gate was near the bottom of the allotment where it flattens out. I mooched about, feeling the ground beneath my feet and how it fell this way and that and slowly got the form in my head about how it should be arranged for maximum use at minimum energy and ultimate benefit to the family.

Later, I managed to recruit Ralph and together we started to get to grips with the levels. There were moments of fractiousness in the otherwise cordial Edwards relations as we battled out how to go about the plan.

Ralph continues: “I was concerned about the terracing. There was no question that it was beneficial. The pocket had filled with topsoil to such a degree that the north east corner (the natural entry point from the house) sloped at close to 45 degrees. This made walking difficult and cultivation would most likely result in the fertile top soil being eroded further down the hill.

My first worry was that the top soil would be shallow and we would hit the bed rock before we were able to sculpt a useful terrace. We therefore decided to prototype the top terraces in line with Sabina’s plan using softwood stakes as shuttering to test viability. The outcome of this was very positive. I have never encountered such perfect soil. I kept picking it up and marvelling at its consistency as we worked. There was plenty of depth for what we needed and quality of the soil meant that it was easy to work with.

We quickly had the top terraces shaped and filled. At this point my second worry occurred; how could we make these changes more permanent? The terraces as we had built them were unsustainable. My judgment was that a wet winter and the work of the local mole population would overwhelm the fragile terraces in a season making them practically useless and maybe a liability. We needed a structure in place that would sustain the terraces for a period of time sufficient for productivity. For a vegetable garden, I would be looking for 3-5 years.

Our challenge was cost and time. In an old life, many years ago, I worked for a short time in landscaping. The plan would be drawn and suitable materials selected for the structure (hard landscaping) which would be put in place before the soft landscaping (soil shaping and planting) was done. The budget and manpower would be set according to the work that needed to be done. The house project was quite rightly the priority for budget and labour. The garden project therefore had to operate on the assumption that it had no significant budget and limited manpower.

The material we had on site that ticked the longevity box big time was the stone. There was lots of this on site in various places; both the local mudstone and harder limestone salvaged from the building work. Working with stone (for me at least) takes time. It is also labour intensive requiring many hands to sort and transport the heavy material made even harder by the sloping site. I also questioned whether the stone would be more valuable for house building. Stone would therefore be used sparingly in the area it was most needed creating the steps on the east side.

The woodland below the site was also a potential source of material. There was plenty of overgrown hazel coppice that needed dealing with anyway and could provide a retaining wall in a palisade style. The downside of Hazel is that it is not particularly durable in the ground. Three years would be about its limit. The coppice was also down the hillside making its transportation very labour intensive.

There were many old oak beams salvaged from the house that were too twisted, worm eaten or nail filled to be reused. These could provide useful retaining walls laid horizontally and would tick the longevity and simplicity boxes. The downside of this material is that it would not go round curves easily and is thick, taking usable space out of the prototype beds.

Finally, there was a pile of Acacia fencing stakes available that were too twisty for easy use in fencing and could therefore be spared for the garden.

I spent a morning down in the coppice felling an overgrown Hazel stool that stood at five metres or so, the main stems being 100-150mm in diameter. I dragged the usable material up the hill and cut it to shape to create a palisade. The morning’s work resulted in just one metre of palisade. I concluded that the time spent felling, dragging, shaping and hammering made the large scale use of Hazel as a palisade a non starter given the time we had available quite apart from durability concerns.

We looked again at the Acacia stakes. I had not used these before but they are truly amazing. They are very resistant to splitting, take a good point and are very durable in the ground. We decided to use these to provide long term support for the terraces by banging them in on the downhill side of the softwood stakes. We then wedged low quality mudstone behind to provide further support.

Aesthetics are an important component of any garden. At this point we had definitely not ticked this box in any way. The treated softwood cladding (a bi-product from the construction of the new roof) was functional but very unattractive. We needed a way to cover it or at least soften it to make the garden sit easily in the land and a pleasant place to be.

I had hoped that the Hazel coppice would yield long flexible material that we could weave through the Acacia posts to cover the cladding. Unfortunately my morning’s work in the coppice yielded just two usable pieces. The coppice was just too overgrown. We tried using thicker shorter pieces but they would not fit behind the posts. Finally, I tried splitting the hazel with a bill hook which proved remarkably easy and the thinner material fitted better. The finished result is still not perfect but we are hopeful that the mint that grows everywhere on the site will colonise and soften the edges further.”

Anyway, whilst Ralph was thinking through all of this, searching and trying difference things, I cracked on with the weeding – which was immeasurably satisfying because, as Ralph mentioned, the soil is gorgeous to work with. I had lots of fun chucking bindweed, nettle roots and mint roots out over the fence and down the slope where Zai the dog raced round trying to catch it all.

Ralph continues: “Once the top terraces were secured I started on the steps. They were to go from the north east corner of the site and had a steep drop to their right (as you look up). I decided to bed them in with mortar on shallow concrete footings. It may have been possible to ‘dry stone’ them but I have no experience of this so decided to stick with what I know to secure the outcome.

Use of hard landscaping across a drainage plane (as the steps were) has to be used with care. If the steps impeded the water the beds could become waterlogged. If the steps channeled water down their upper side they and the raised beds they serve could be rapidly eroded under extreme conditions. I therefore decided only to use mortared stone on the step edge and fill in the treads with gravel. This should allow water to flow as it always had done down the hill limiting the possibility of nasty side effects.

The design book says that the riser height on garden steps should ideally be 150mm with the tread 300mm minimum. We wanted to be able to be able to place a barrow on the steps level with the terraces so these would need to be 600mm at least.

If we had done a proper site survey and design before we built the terraces and steps we would have known that our site tested these constraints. In practice, the steepness was such that the lower section has risers of 200mm and the 600mm target had to be sacrificed. This is no huge deal in the scheme of things but does clearly show the value of a more methodical approach.”

Three days in to our Allotment makeover, we met three remarkable American and two pretty awesome Swiss guys. Rick, Syd and Pete were from Washington and are part of the JOY Travel USA.

The Americans scored a lot of points digging out the decades old pig manure from the silo in the Basarria and delivering it next to the new gate that was added to the top of the allotment.

Fred and Andreas we had met at the Christian Surfer’s International Conference in Hossegor. Andreas is a plumber and Fred a nurse, together they worked on sorting out the plumbing and drainage for the Txabola where Joseba and Joanna were living. It was very handy having them about.

Our friends, Mike and Portugal Bob who had caught up with us whilst in Hossegor, popped in on their way back from Portugal and whilst Bob chilled in their van, Mike gave us a hand whacking in the softwood pegs to screw the cladding on to shore up the terraces. It was great having them around and we had a lovely meal together that evening before they continued their journey back to England.

The following day, after a delayed start and another slap-up meal at the local bar, we didn’t get into the allotment until well past 4pm. Fred and Andreas were busy with the drains, Ralph was starting the top step, I was alone with the sledgehammer.

Click here to see what happened next. (Caution: Graphic images)

I was quite calm at first, Fred asked if I was okay, I said yes. Then I started to panic and whilst shouting at Ralph for no apparent reason, Andreas just quietly bandaged my hand – mind you, it was the least he could do as he’d shut the water off!! Ralph’s face as I bled all over our van’s kitchen but it was the only place with running water – I had to clean it somehow, though! Joanna arrived home with Nahia just in time and she turned the car straight around and took me to Gernika hospital. The whole process was remarkably quick, efficient and calm. Joseba came and took over so Nahia could get home and sorted my medication out before driving us home. Thank you everyone for taking such care of me – old duffer that I am 🙂

The following day, I had to go to Lekeitio to get my stitches checked – all 11 of them. This was convenient because we had heard that Ricardo was in town visiting his family and we had arranged to meet at the skatepark. Andreas came too and we had a cool few hours hanging out – I took photos, tempting as it was to have a go, Ralph was not happy at that thought. You can see the pix from the skatepark here.

Back in the allotment …

I carried on as best I could, taking a few days here and there to recover and chill, using this enforced R&R to crack on with my BSL course which I am doing online. Having said our goodbyes to both the Americans and the Swiss we were now awaiting the second batch of Americans, from Oregon. Ralph continues:

“During the week that the Oregons were with us, we continued the build of the first section of steps. I was desperate to find time to fill them with gravel so that they looked like steps. Without the gravel they looked like a series of obstacles and we got tired of explaining to nonplussed observers what they were. When I eventually got time off from the house build to pour the gravel I found that it had been used for concrete necessitating a long lunch before Joseba was available for a quarry trip.

This is the right time for an aside on the subject of the quarry. I have never come across such a pleasant, convenient and sustainable approach to the problem of aggregate collection before. First base in the UK is B&Q or Wickes where the aggregate is in 25kg plastic sacks. Huge carbon footprint on that one. Second base is the bulk bag delivered on a truck. Much better, but there is not much aggregate in a bulk bag and it costs sixty quid. Third base is the truck load delivered and dropped on your drive. Expensive and you have to shift it before you can get the car out.

At Olabe, you pop the trailer onto the back of the car and drive to the quarry ten minutes away. You can see the rock face being quarried along with the machinery that grade the material and deliver it into huge silos large and high enough for an articulated truck. The car and trailer is weighed on the weigh bridge. You then drive under the silo of your choice and pull a lever which releases the aggregate into the trailer from height until the tyres bulge. You then drive back to the weigh bridge to be weighed and pay. Finally you drive back to Olabe at breakneck speed as if you had no trailer and a ton of aggregate on board. We never paid more than twenty euros for a load.

With a new trailer load of gravel we were able to fill in the first section of steps with gravel. It made a huge difference. Now people started to wander down the steps and sit on the raised beds; exactly the type of reaction and atmosphere we wish to create.

In the next week I completed the remaining steps to reach a more level area. There proved to be far more steps than we originally anticipated but we are pleased with the end result.”

The Oregons were making incredible progress in the house and I was able to snaffle away Liz to help me in the garden – she’s probably the best grafter in the world so I was well chuffed when she said she’d be happy to help me! We had a blast!

Between us we worked out who was better at what; Liz did the hammering in (I’m not allowed near a sledgehammer anymore, anyway) and I did the sawing. We kept having to chase the chickens out and giggled every time we turn our backs only to find more chickens sneaking in.

Between us we worked out who was better at what; Liz did the hammering in (I’m not allowed near a sledgehammer anymore, anyway) and I did the sawing. We kept having to chase the chickens out and giggled every time we turn our backs only to find more chickens sneaking in.

We worked hard on one of the largest beds and the steps that were to run along in front. Working with Liz was definitely a lot of fun and one of the highlights here at Olabe. Joanna took over to help get the manure in place and the bed was finished.

Ralph continues: In the lower section there were more straight lines allowing us to frame quickly using the old oak beams. The beams were secured mostly by drilling and hammering through reinforcing bar to pin them to the ground and each other. We also used Acacia posts in some places where we felt that they might become overwhelmed by lateral forces.

“Looking back at what we have done, I am pleased with the outcome. The design was ambitious given the manpower and budget available. But there is now a lasting structure in place that can be worked on and extended over time. We hope the terraces will last for three years and when they start to fail they can be repaired easily using simple techniques. Perhaps the shuttering could be gradually replaced with dry stone wall over time for a more permanent and aesthetic finish.”

Photos : with thanks to Olabe and crew.

Hellooooooo Ralph and Sabs!! loving your blogs – keep ’em coming! The work you’re both doing looks just great – how’s that hand of yours? xx. All ok here in Exeter- revving up for Christmas now with lots of Church festivities etc to plan- I’m making Shepherd and Angel ‘kits’ for possibly 150 kiddies, and then doing demonstrations so that other people can lead the activities- a most enjoyable thing to do!! miss you both but so happy that you’re having this great experience x. Have you thought of a book when you have collated all your adventures??!!! Take care fabulous people much love Mel xxx

LikeLiked by 1 person

wow guys. what an amazing achievement. well impressed. Poorly finger as well. brave girl. take care. x

LikeLiked by 1 person

Nice to see the finished product! God prepared you both very thoroughly to accomplish everything we see here. Great job following through on God’s work.

LikeLiked by 1 person

Hi Sabina. I was a bit too squeamish to look at the gory photos so I don’t really know what happened. However, I hope you have now recovered and that there’s no lasting damage. 🤞 Enjoy your continuing adventure! Barbara & Brian xx

LikeLiked by 2 people

It’s all good now and thankfully healed really well. It wasn’t pretty! Lovely to hear from you 🙂

LikeLike